Coil winding technology - Wikipedia

In electrical engineering, coil winding is the manufacture of electromagnetic coils. Coils are used as components of circuits, and to provide the magnetic field of motors, transformers, and generators, and in the manufacture of loudspeakers and microphones. The shape and dimensions of a winding are designed to fulfill the particular purpose.

Guide to Transformer Windings & Coils - maddox.com

2024年12月23日 · Learn all about how windings work, different winding designs, & what's best for your unit. What are transformer windings? Transformer windings are coils of copper or aluminum, wrapped around the transformer’s core. They determine what voltage is produced and whether that voltage is stepped up or down.

The Basics of Coil Winding - Custom Coils, Inc.

2023年12月5日 · Coil winding involves wrapping a wire around a cylindrical object in a spiral-like shape to produce a standalone coil or a coil on a toroid, bobbin, or other type of center support. The coil may be made of one or more layers of wires depending on its intended application.

Coil Winding Machine: Introduction, Types, Working Principle & Process

Coil windings are found to be structured into various groups regarding the type and geometry of the wound coil. The mass production of electromagnetic coils relies on the automated machinery only. Based on the common mechanism of working, coil winding machines are commonly known to be of different types, which are as follows.

Coil Winding Basics - Sciencing

2020年12月27日 · The linear winding method of coil winding creates windings onto rotating coil bodies or coil-carrying devices. By forcing the wire through a guiding tube, engineers can mount the wire onto a post or a clamping devices to remain secure.

Coil Winding: Definition, Methods & Application - HBR Industries

Coil winding is the process of wrapping wire or tube around a cylindrical form or other forms of continuation of spiral like method to create a coil either on a center support like a bobbin or toroid, and as a standalone air coil.

The Intricate Art of Coil Winding: How Precision Shapes Power

2023年9月29日 · Coil winding involves the strategic arrangement of wire around a core to create coils, which are fundamental building blocks of various components. The process is a delicate balance between the precision of winding machines and the expertise of operators.

The 4 Main Types of Motor Windings And How To Test Them

2025年2月4日 · 1. Stator Winding. The stator winding serves different roles whether it’s in a DC or AC motor. In the former, it generates a constant magnetic field, while in the latter, it produces a rotating magnetic field. In some cases, it also functions as both the field and armature winding in AC motors. 2. Rotor Winding

Behind the Scenes: Exploring the Inner Workings of Coil Winding ...

Coil winding machines automate the winding process, ensuring consistency, accuracy, and efficiency. These machines come in various types and configurations, each tailored to specific winding requirements.

What are the different types of coil winding? | Miles Platts

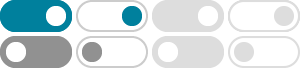

2024年7月9日 · Random coil winding, orthocyclic winding, helical winding, and jumble winding are all methods used in the manufacturing of electrical components such as transformers, motors, and inductors. Each winding technique has unique characteristics and advantages depending on the intended application.

The Evolution of Precision Coil Winding Machines - Itasca

2024年12月6日 · Today, coil winding machines have evolved to provide exceptional levels of precision, versatility, and efficiency. Modern automated coil winding machines are equipped with advanced features, including multi-axis motion control, programmable logic controllers (PLCs), and touch-screen interfaces.

Coil windings - E-Mobility Engineering

Some electrical machines create all their magnetic fields by passing electric currents though coils of wire wound onto cores, while others use a combination of permanent magnets and coil windings. These windings may be in the machine’s rotor or stator, or both.

A matter of coil winding - electricmotorengineering.com

Automated and semi-automated winding machines are increasingly sought after due to their ability to handle complex configurations and minimize human error. GROB Italy stands out in the field with three advanced solutions, specifically developed to address its customers’ needs. 1. Flip: enhancing efficiency at high frequencies.

Coil Winding Machine: Introduction, Types, Principle

2021年12月24日 · Coil windings are useful as a circuit element to deliver a magnetic field to motors, transformers, and generators and is also a valuable tool for microphones and loudspeaker manufacturing. Winding machines come in shape and dimensions to …

Field coil - Wikipedia

Coils are typically wound with enamelled copper wire, sometimes termed magnet wire. The winding material must have a low resistance, to reduce the power consumed by the field coil, but more importantly to reduce the waste heat produced by resistive heating. Excess heat in the windings is a common cause of failure.

What is Coil Winding - Benatav

Coil winding can be categorized into several groups based on the type and geometry of the wound coil: wild or jumble, helical, and orthocyclic. Machines that wind coils in a helix create layers and switch directions, moving forward and backward.

Coil winding technology means to wind an electrical conductor to a compact structure, a coil. Thereby, geometric structures develop by single or multiple windings, which may be layered in single or multiple layers.

Handbook of Coil Winding - Springer

2017年9月1日 · This book presents the current coil winding methods, their associated technologies and the associated automation techniques. From the introduction as a forming joining process, over the physical properties of coils, the semifinished products (wire, coil body, insulation) are introduced.

Everything to Know about Coil Winding Process - My Blog

2023年6月5日 · With the help of the winding process, an insulated copper wire around a pin or core prepares a coil. However, the micro-coils can be coreless and self-bounded this means during the winding process, the coil is tied to itself. The winding process can occur around rectangular or cylindrical support.

Coil Winding Basics: What You Need to Know | zhcoils.com

Coil winding is the process of wrapping wire around a core to create a coil. These coils are essential parts of many electrical devices like motors, transformers, and inductors. The design of the coil and the winding technique used depend on the specific needs of the application.

Coil Winding - Prem Magnetics

Our vast custom coil winding service makes us the perfect choice to complete coil winding projects for countless industries and applications. We’re fully equipped with coil winding machines, including automatic transformer coil winding machines and hand coil winders.

Coil Winding - Remington Industries

Our expert team can help you determine which type of coil winding is best suited to your project, and provide you with wound coils you can trust. Popular coil winding services include: Linear winding; Toroidal core winding; Bifilar and trifilar winding; Coil Winding Machines

- 某些结果已被删除